Seating, beds, upholstered furniture, from the prototype to mass production.

We are your upholstery workshop and your production line, able to support you in the

industrialisation and mass production of all your products. The ability to manage the complete

supply chain, from fabrics to frames, ensures excellent results even for complex products.

A craft focus yet organised according to industrial systems for series production of

your... one-off items.

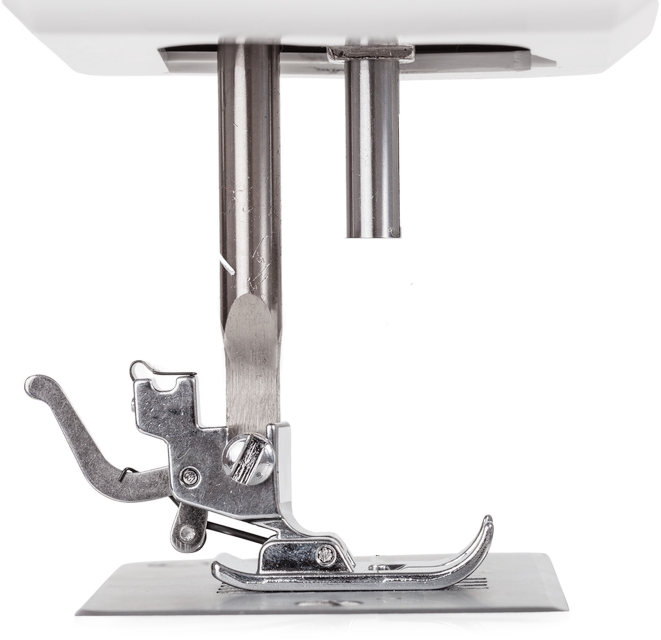

CHAIN FOR ALL-INCLUSIVE

PRODUCTION

From the order to packaging, all your products are

ready for delivery to the customer. The ability to monitor

a complete supply chain, from frames to fabrics, from

covering to manufacture and assembly to packaging

according to the criteria agreed.

We optimise production according to a just-in-time concept which allows

a fast launch of production of only the pieces that you actually need.

Our production line will be your only “warehouse”: speed, lower costs and

rationalised production to fulfil one, ten, a hundred orders.

OF FABRICS

BENCHES